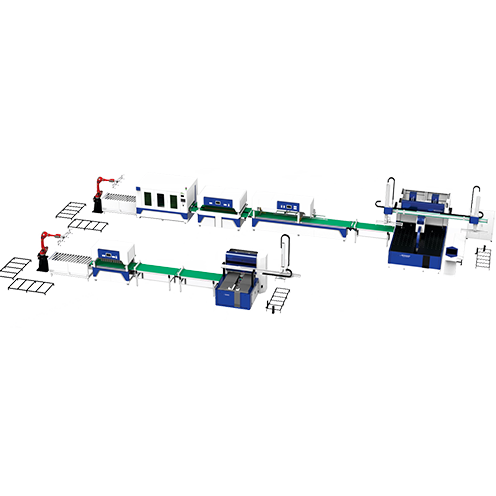

Large-scale sheet metal processing enterprises (such as steel office furniture factories, commercial kitchenware factories) need to process standardized sheet metal in bulk.

Applications: Steel office furniture (filing cabinets, desks, etc.); Commercial kitchenware (stainless steel kitchenware, kitchen equipment); Medical devices (medical equipment shells, accessories); 5G accessories (metal structural components for 5G base stations); Electrical and electronic (electrical enclosures, distribution cabinets); New energy (metal parts for new energy equipment).

+86-13585707741*24-hourWhatsapp/Wechat

Bending automation integration: With truss system for automatic loading of multiple specifications of sheet (width 300-1000mm, length 500-2000mm); Unmanned operation: No human intervention throughout the process, supporting multi-device collaboration; Efficiency improvement: Significantly shorten the production cycle and enhance the efficiency of batch production.

Hanqi provides "pre-sale - in-sale - after-sale" full-process service to ensure customer experience.

Consultation support: A professional marketing team provides product consultation and technical answers.

Customized solutions: Engineering designers conduct on-site surveys and customize exclusive solutions based on customer production requirements.

Production assurance: Organize production as stipulated in the contract to ensure the delivery cycle.

Logistics and transportation: Provide fast and safe logistics and transportation services.

Installation and commissioning: An experienced technical team installs and commissioning on-site, with full supervision to ensure the normal operation of the equipment.

Warranty period: The product is guaranteed for 1 year, and lifetime maintenance services are provided (free during the warranty period, only the cost of materials is charged outside the warranty period).

Follow-up mechanism: Regularly visit customers to understand the usage of the equipment and provide operation and maintenance suggestions.

Response speed: Respond to customer complaints and repair requests within 24 hours.

Hanqi's core components are all from well-known domestic and international brands to ensure product stability and precision: Electrical:

Panasonic, Omron, Schneider, Keyence, Fuji Electric;

Mechanical: NSK (bearing), NACHI (bearing), Rexroth (valve group), HIWIN (guide rail), TVBS (guide rail);

Core components: AMADA (frame/mold supplier), Mitsubishi (motors), Hachuang (motors), British Trio (controllers), etc.