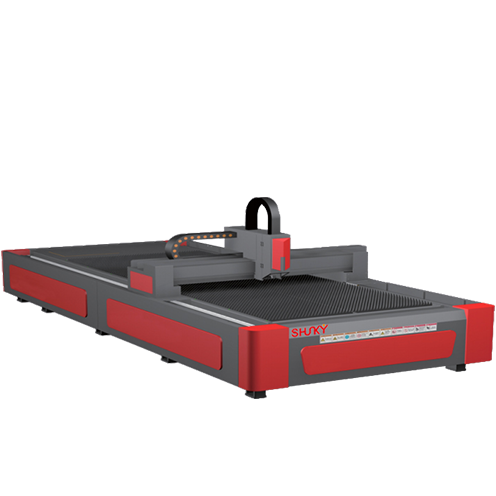

Laser platform cutters are primarily used for non-contact, high-precision, high-efficiency two-dimensional shape cutting of metal plates. It can replace traditional processes such as punch presses, shearing machines, plasma cutting, wire cutting, etc. to achieve rapid prototyping of complex shapes.

Applications: Carbon steel (especially high-quality cuts under 2mm);Stainless steel Aluminium alloy;Galvanized sheet, electrolytic sheet;Silicon steel, titanium alloy, brass sheet and many other metal materials.

13585707741*24-hourWhatsapp/Wechat

Fiber laser cutting machines use CNC systems that represent the most professional laser processing. Compact and modular, it meets users' demands for high-performance CNC systems at a good cost performance. Open system: A truly advanced open numerical control system that allows users to integrate third-party professional software or technology into the system. At the same time, it offers a range of open tools that allow users to customize their own personalized interface and the special functions they need.

Well-structured: Advanced system design architecture, with all system software running on the main PLC processor instead of the traditional dual-CPU design concept.

Leading-edge technology: More than 20 years of experience in the application of CNC technology based on PLC platforms. All functions are open to users in a modular form without any hardware modifications.

Superior performance: Perfect three-axis linkage and coordinate transformation capabilities for complex multi-axis and multi-channel coordinated control to meet the application requirements of all kinds of CNC equipment.

High-speed operation: Optimized control algorithms ensure high-speed control at 240 m/min with a resolution of 1 micron, making it the best choice for high-speed, high-precision CNC machines.

Perfect functionality: It offers a wide range of functional options and optimizes the configuration of functions based on application fields, achieving the most perfect balance between performance and price.

Laser platform cutters are primarily used for non-contact, high-precision, high-efficiency two-dimensional shape cutting of metal plates. It can replace traditional processes such as punch presses, shearing machines, plasma cutting, wire cutting, etc. to achieve rapid prototyping of complex shapes.

Extremely high machining accuracy with excellent cutting quality.

Exceptional flexibility with "mold-free" machining.

High-speed and efficient processing capabilities

Powerful integration of automation and intelligence.

Supports multiple cutting gases for wide applicability.

The laser platform cutting machine is an indispensable flexible, precise and efficient sheet processing tool in modern manufacturing. With its "mold-free" processing method, ability to handle complex graphics and excellent processing quality, it has become an all-rounder from large sheet metal structural parts to precision electronic components. For enterprises that seek quick market response, frequent product iterations and high processing quality requirements, the laser platform cutting machine is the key equipment to enhance core competitiveness.

| Laser platform cutting machine | |

| Optional power | 1500W/2000W/3000W |

| Cutting range | 2.5-1.25m |

| Cut sheet (coil) | Strip steel, galvanized sheet, stainless steel sheet, etc |

| Z-axis travel | 120mm |

| The loading rack bears the load | ≤8 tons |

| Feeding mode | Servo roller feeding |

| Maximum feeding speed | <30m/min |

| Leveling thickness | 0.3 mm to 1.2 mm |

| Operating voltage | 380V, 50HZ, 100A |

| Slit width | 0.1 0.5 mm |

| Cut roughness | Ra3.2 |

| Operating ambient temperature | 0 ℃ and 40 ℃ |

| Operating environment humidity | <70% |

| Maximum load on the workbench | 200Kg |

| Total power supply protection class | lp54 |

Core configuration

| Project | Name | Brand |

| Machine bed | Integral welding, precision machining of machine bed | Patent developed by China Hanqi |

| Crossbeam | Integral cast one-piece gantry beam | Patent developed by China Hanqi |

| Z-axis module | Z-axis high-speed drive system | Patent research and development by China Hanqi |

| Electronic control system | Dedicated electronic control board and independent control cabinet | Patent developed by China Hanqi |

| Laser | Fiber laser | Optional from Shenzhen Laser Fiber laser Chuangxin/Ruike, China |

| Cutting head | Precision special laser cutting head | Optional Shanghai Jiaqiang/Wanshunxing, China |

| Water cooler | Laser-specific dual-temperature dual-control water cooler | Hanli, Wuhan, China |

| Numerical control software systems | Operating system for laser cutting | Shanghai Jiaqiang,China |

| Reducer | Disc planetary reducer (Fran connection) | Modori, China (France) |

| Guide rails | Ultra-precision linear guides | Tai Wen, Taiwan, China |

| Rack | Grade 6 high-precision grinding rack | Tai Wen, Taiwan, China |

| Servo motor drive | Each axis motor and driver | China Hechuan |

| Proportional valve | High-pressure proportional valve | SMC Japan |

| Solenoid valve | High-pressure solenoid valve | Airtac Taiwan, China |

| Check valve | High-pressure check valve | Taiwan, China Airtac |

| Circuit components | Control cabinet components | Chint China & Omron Japan |

| Pc Industrial computer | Anti-interference industrial computer | Chinese Hanqi patent Design Custom |

| Protective cover | Waterproof, oil, fire, dust, heat resistant shield | Chinese Hanqi patent design Custom |

| Drag chain | Protective drag chain | China Hanqi Patent Design Customization |

| Cable | Flexible cable | Chinese Hanqi Patent Design Custom |

| Lubrication system | Fully automatic lubrication system for rack and guide rails | Chinese Hanqi patent design Custom |

| Material rack | Customized loading rack | Customized by Chinese Hanqi patent Design |

| Leveler | Multi-roller this friend mucarries 拝 library leveler | Chinese Hanqi patent design custom |

13585707741*24-hourWhatsapp/Wechat